Subject to production capabilities. Art deviating from WCI specifications will require production approval or customer sign-off.

Flexographic Printing Specifications:

- Finest line screen: 55 Line Screen at 15%. Screening may be subject to run as a separate color upon production review of artwork (based on machine parameters).

- Registration Factor: 1/8” plus or minus. Colors may not move in the same direction at the same time.

- Side-to-side alignment tolerance: 1/16”.

- Logos containing fine detail and small reverses may fill in.

- Minimum Font Size:

- Positive: 6 pt. Helvetica.

- Negative (reversed out): 9 pt. Helvetica.

- Minimum Line Weight:

- Positive: 1/64” (1 point).

- Negative (reversed out): 1/32” (2 point).

- Gusset printing available (approval required for more than 25% ink coverage in gussets).

- On two-sided print: Seam placement to be determined by production and machine capabilities. Back seam match-up may vary.

- Artwork may not bleed off back edge of bag. Allow 1/16” space from edge of bag.

Post Print & Hot Stamping Specifications: Post printing provides an opportunity to print in an offline process. This process doesn’t afford the same opportunity for color, clarity, consistency of position or complexity of artwork. Due to the limitations of the offline process the expectations need to be understood prior to placing an order as there will be no returns accepted relative to the listed items. WCI will do its best to provide a quality product as close to our inline printing capabilities, however with the understanding it may not able to achieve the above parameters with the offline process.

- Screening Capabilities:

- Hot Stamp: No screening available.

- Post Print: 55 Line Screen at 15%.

- Registration Factor:

- May vary up to 1/4” in either direction.

- Product is printed/stamped on bags already produced; copy position subject to adjustment at time of production in an effort to optimize printing quality.

- Side-to-side alignment tolerance: 1/8”.

- Positive images preferred. Less than 25% coverage.

- Copy placement and print quality subject to thumb notches, seams, gusset creases, etc. Subject to production approval.

- Imprint size capabilities as noted on template.

- No special ink colors for Post Printed orders.

- Maximum Order Quantity:

- Hot Stamp – <5,000 bags

- Post Print – 5 cases

Digital Printing Specifications:

- Min and Max: Suitable for orders ranging from 1 case up to 5000 bags, aimed at small to medium-sized orders.

- Bag Color Options: White (recommended), Recycled Natural, and Colors; darker colors recommended for kraft or colored bags for optimal ink appearance.

- Imprint Location: Front and back imprinting available, excluding gussets.

- Imprint Size: Maximum size of 24 inches for one side, with the largest printable area being 11-1/2 inches wide; prints can be placed up to 1/4″ from the bag’s border. Note, placement may shift by up to 1/4″ in any direction.

- Artwork and Files: High-resolution PDF, EPS, or TIFF formats. High-quality PNG and JPG files are also accepted but print quality may be impacted.

- Resolution and Color: Up to 300 dpi for clear images and text, with a 600 dpi option available; CMYK color process used, no Pantone matching, and digital printing provides less opacity than flexographic printing.

Proofs/Ink Drawdowns/Lead Time

Proofs are sent on all orders with new or revised art. One set of proofs will be included at no charge. Additional proofs will be billed at a cost of $40.00/proof. Outturn production samples sent upon request. WCI is happy to provide proofs and drawdowns during the quoting stage with a submitted Purchase Order requesting proof or drawdown. Any cancelled purchase orders or speculative work not resulting in a PO within 60 days will be billed at costs listed above.

Ink drawdowns are available for custom printed jobs and processed in the following manner:

• Stock inks – Sent upon request only. $25.00 processing fee.

• Custom ink matches – One set of drawdowns will be sent unless noted on PO. Cost included in special ink fee. Additional drawdowns – $25.00/color.

Proof Approval: All proofs must be signed and returned before lead time can begin. No credits or returns will be allowed for any component in accordance with the approved proofs.

Lead-Time: Lead-times are approximate and begin when art and ink are approved. Changes after approvals may incur additional charges/delays.

Art Charges: Any additions, deletions, or changes to artwork will be charged at cost. An estimate will be provided and must be approved before any art changes will be made.

Plate Specifications:

Customer must sign a print release form when they supply plates for printing. All plates are subject to WCI production approval prior to production:

-

- Customer-supplied plates accepted for 1-sided print only. For 2-sided print, please call to discuss plate requirements.

- All plates are subject to WCI production approval prior to production.

Plates not within spec may be refused and/or may cause print quality issues.

- For scheduling purposes we require a separate set of plates for each bag size ordered; even if art size is the same.

- Plates with sticky backing will not be accepted.

- 1/2″ flashing all around the plate.

- Please call for distortion information requirements. Failure to distort plates can cause production delays, added costs, and print quality issues.

- Centerlines are required on all plates.

- WCI is not responsible for the maintenance, condition, or return of printing plates.

- Copy of artwork must be sent with plates.

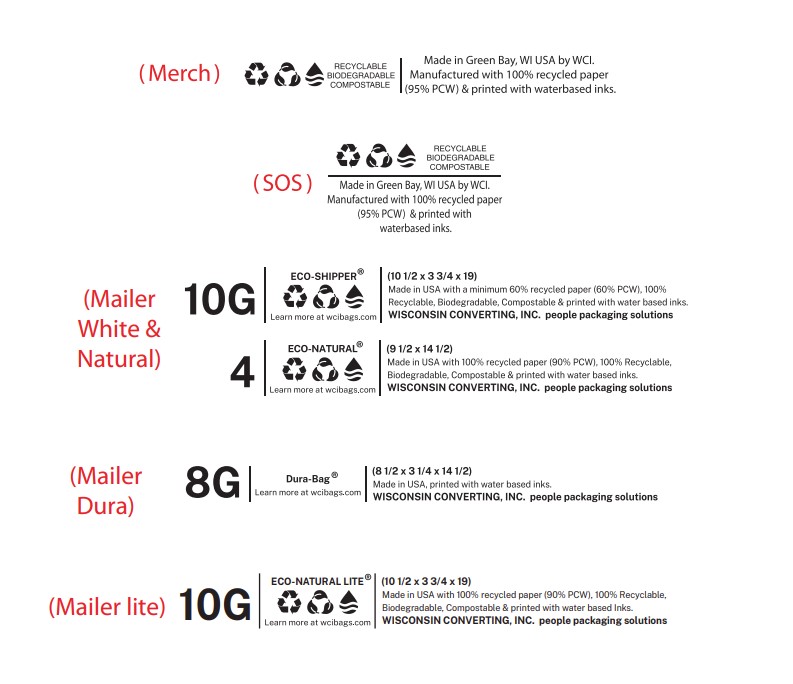

Merchandise, SOS, & Gourmet Bags:

Bag length of 9″ and less: 2 plates per color.

Bag length of 9 1/4″ and more: 1 plate per color.

Photopolymer Plate Requirements: Sheet photopolymer plates are preferred to liquid photopolymer plates. If screening, sheet photopolymer plate is required. Place a sheet of paper between the photopolymer plates to prevent damage.

- Thickness for sheet photopolymer: .107 to .112 (.050 relief)

- Thickness for liquid photopolymer: .110 (.050 relief)

Hot Stamping Die Specifications: .250 Magnesium Die (.0625 to .09375 relief) with centerlines.

Standard Bottom Turnover Text:

Art Charges: Any additions, deletions or changes to artwork will be charged at cost. An estimate will be provided, and must be approved before any art changes will be made.

Plate/Die Charges: Plate/die charges subject to review of actual art and graphic size and do not include any alterations or file clean up. Any plate charges necessary to produce your order will be provided when you receive your proof. WCI Plate Cost Calculator

Any charges necessary to produce your order will be indicated on your proof, as proof approvals are required before order can be produced.

For assistance in calculating plate costs for your art please use our WCI Plate Cost Calculator

Art Charges: Any additions, deletions or changes to artwork will be charged at cost. An estimate will be provided, and must be approved before any art changes will be made.

Plate/Die Charges: Plate/die charges subject to review of actual art and graphic size and do not include any alterations or file clean up. Any plate charges necessary to produce your order will be provided when you receive your proof. WCI Plate Cost Calculator

Any charges necessary to produce your order will be indicated on your proof, as proof approvals are required before order can be produced.

Flexographic Ink Specifications: Printed bag prices based on stock ink colors. Special Pantone (U) ink colors will be charged special ink fees. Orders of less than 25m – will be charged $75.00 per color per order; more than 25m bags will be charged $50.00 per color per order. Custom ink fee includes one ink drawdown for approval. Custom ink matches other than PMS colors and custom metallic inks – per quotation. Stock metallic ink – add 15% to total product cost. Substantial metallic ink coverage subject to review. Custom metallic ink not available. All inks can vary in color due to paper, ink, machine, and ambient lighting differences. Ink colors are based on printing upon white paper in ideal conditions. Due to the nature of waterbased ink, colors will change when printed on colored paper. Therefore, if WCI is required to match a Pantone color on colored paper (regardless of PMS number) a special match charge will be added.

Ink drawdowns are available for custom printed jobs and processed in the following manner:

- Stock inks – Sent upon request only. $25.00 processing fee.

- Custom ink matches – One set of drawdowns will be sent unless noted on PO. Cost included in special ink fee.

- Additional drawdowns – $25.00/color.

WCI is happy to provide proofs and drawdowns during the quoting stage. Any cancelled purchase orders or speculative work not resulting in a PO within 60 days will be billed at costs listed above.

For assistance in calculating plate costs for your art please use our WCI Plate Cost Calculator

Art Charges: Any additions, deletions or changes to artwork will be charged at cost. An estimate will be provided, and must be approved before any art changes will be made.

Plate Charges: $150.00 per color per art size. Includes art processing, film prep and plate charges. Cost dependant on camera or digital ready artwork provided to WCI specifications. Art and plate estimates are available from customer service. Estimates subject to review of actual art supplied by customer. Any charges necessary to produce your order will be indicated on your proof, as proof approvals are required before order can be produced. Print name must be provided prior to order acceptance.

Registration Tolerance & Trap: Wherever two colors meet, a 4.5 point trap – 1/16″ – is required to trap the colors. Where two colors are adjacent and the designer does not want them to touch, there should be a minimum of 1/4″ of space between the two colors. As a general rule this register tolerance precludes the use of two overprinting colors to create a third color, whether with solids or screens; and when attempted would need a third color such as black to outline the shape. Note that due to our production process, there is no trapping or overprinting on Claycoated paper.

Line Width & Type Size: Minimum positive printing line width is two (2) point. The minimum reverse printing line width is (3) point. Minimum positive printing type size is ten (10) point. The minimum reverse printing type size is twelve (12) point bold. These guidelines are subject to review with serif type faces, and with designs including heavy areas of broad solid along with small type in the same color. In these circumstances the type may need to be larger and/or bolder.

Screens & Halftones: The line screen rulings used in our process are 45 to 55 line. The coarse screen is not apparent and insures cleanest possible dot reproduction. Due to the differences between how wide web flexo and offset litho reproduce screens and halftones, we request the opportunity to review the design elements to provide specific production art direction as early in the planning process as possible. Halftones must have strong contrast, as must steps between manually selected screen values of the same color. Subtle tone variations will not reproduce.

Merchandise Bags:

- 5 x 7 1/2

- 6 1/4 x 9 1/4

- 7 1/2 x 10 1/2

- 8 1/2 x 11

- 10 x 13

- 10 x 2 x 15

- 12 x 15

- 12 x 2 3/4 x 18

- 14 x 3 x 21

- 16 x 3 3/4 x 24

Pharmacy & Liquor Bags:

Concession:

- 2 3/4 x 10

- 3 1/2 x 2 x 8

- 3 x 1 1/2 x 6 1/2

- 3 x 2 x 9

- 4 1/2 x 2 x 9 1/4

- 4 1/2 x 3 1/2

- 5 x 3/4 x 10

- 5 x 1 x 8

- 6 3/4 x 7 (Open Side)

- 6 x 3/4 x 7

- 7 x 1 x 8

Bread Bags:

SOS Bags:

Handled Shoppers:

Gourmet Bags:

WCI Mailers:

- #0 (6 x 10)

- #1 (7 1/4 x 12)

- #2 (8 3/4 x 12)

- #3 (8 1/2 x 14 1/2)

- #4 (9 1/2 x 14 1/2)

- #5 (10 1/2 x 16)

- #6 (12 1/2 x 19)

- #7 (14 1/4 x 20)

- #5G (5 x 2 x 10)

- #6G (6 x 2 3/4 x 12)

- #8G (8 1/2 x 3 1/4 x 14 1/2)

- #9G (9 1/2 x 3 x 16)

- #10G (10 1/2 x 3 3/4 x 19)

- #10G (10 1/2 x 3 3/4 x 19) – Eco-Natural Lite®

- #12G (12 1/2 x 4 x 20)

- #12G (12 1/2 x 4 x 20) – Eco-Natural Lite®

- #18G (18 1/2 x 6 1/4 x 24 3/4) – Eco-Natural Lite®

Merchandise Bags:

- 5 x 7 1/2

- 6 1/4 x 9 1/4

- 7 1/2 x 10 1/2

- 8 1/2 x 11

- 10 x 13

- 12 x 15

- 12 x 2 3/4 x 18

- 14 x 3 x 21

- 16 x 3 3/4 x 24

Handled Shoppers:

Pharmacy & Liquor Bags:

SOS Bags:

- 1# (3 1/2 x 2 3/8 x 7 1/8)

- 2# (4 1/8 x 2 1/2 x 7 7/8)

- 4# (5 x 3 1/8 x 9 5/8)

- 6# (6 x 3 5/8 x 11 1/16)

- 8# (6 1/4 x 3 13/16 x 12 1/2)

- 10# (6 9/16 x 4 1/16 x 13 3/16)

- 12# (7 1/8 x 4 3/8 x 13 15/16)

- 16# (7 11/16 x 4 7/8 x 16 1/16)

- 20# (8 1/4 x 5 1/4 x 16 1/8)

- 25# (8 1/4 x 5 1/4 x 18)

- Modified 1/6 Barrel (11 x 6 x 17)